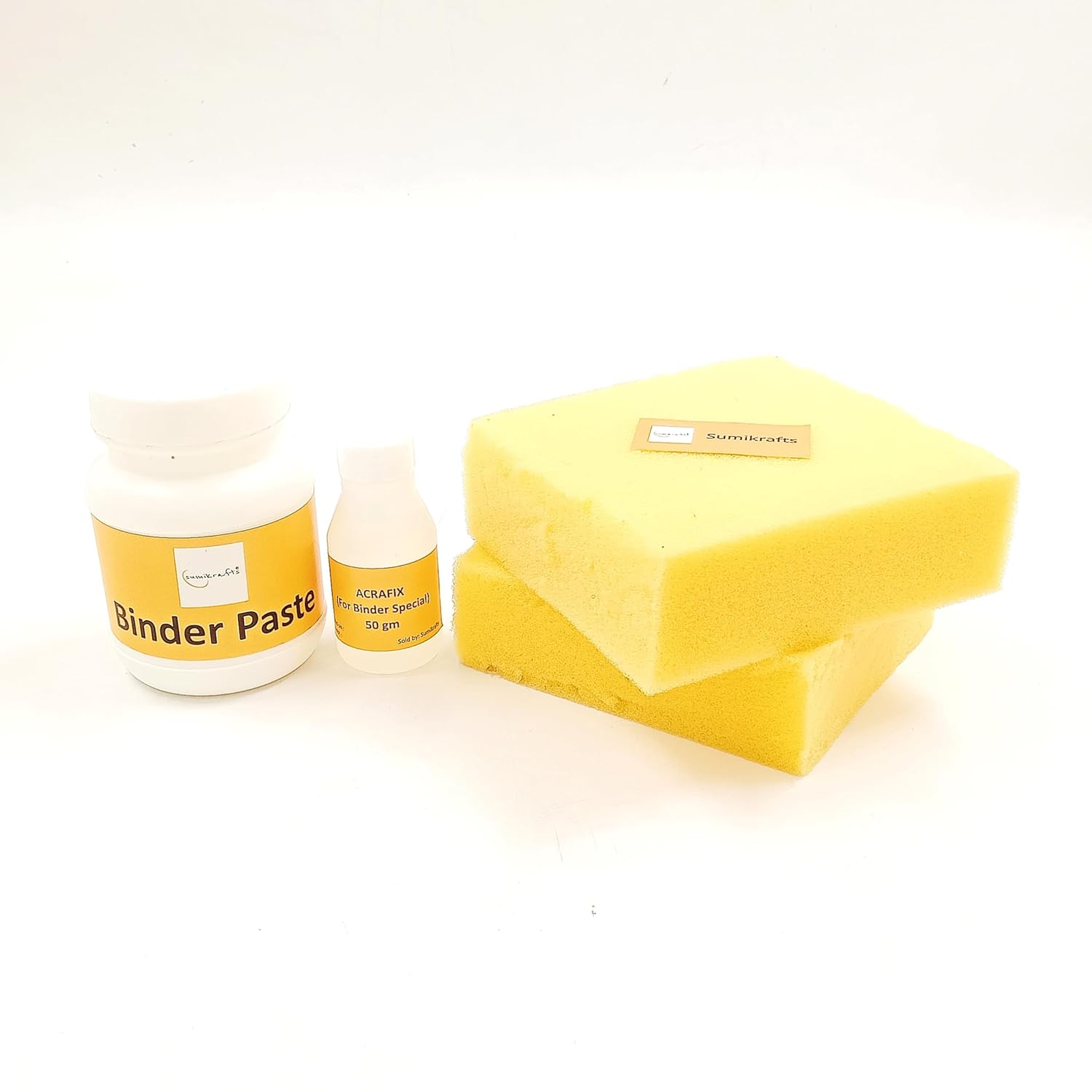

Sumikrafts premium binder paste 400gm-for screen printing-block printing-arts and crafts

- Binder paste is a crucial component in the textile printing process, acting as a medium that carries pigments or dyes and helps them adhere to the fabric. It is typically a water-based, viscous substance composed of synthetic or natural polymers that form a film upon drying. The binder paste ensures the color remains fixed to the fabric, providing durability, wash fastness, and color vibrancy.

- and pigments. It is a chemical compound that, when added to dye or pigment mixtures, facilitates the chemical bonding between the colorant and the fabric fibers. This bonding increases the wash fastness, light fastness, and overall longevity of the printed designs.

- Binder Paste: Uses in Screen Printing: In screen printing, binder paste serves several essential functions: Pigment Carrier: It suspends the pigment or dye evenly throughout the paste, ensuring consistent colour application across the fabric. Adhesion: It helps the pigment adhere to the textile fibers, preventing the colour from washing out or fading quickly. Film Formation: Upon drying and curing, the binder paste forms a thin, flexible film that holds the pigment in place.

- Binder Paste: Uses in Block Printing: In block printing, binder paste is equally important: Pigment Suspension: Similar to screen printing, it ensures that pigments are evenly distributed and suspended within the paste. Adhesion: Facilitates strong adhesion of the pigments to the fabric fibers. Flexibility: Allows for easy application with hand-carved blocks, transferring intricate designs onto the fabric.