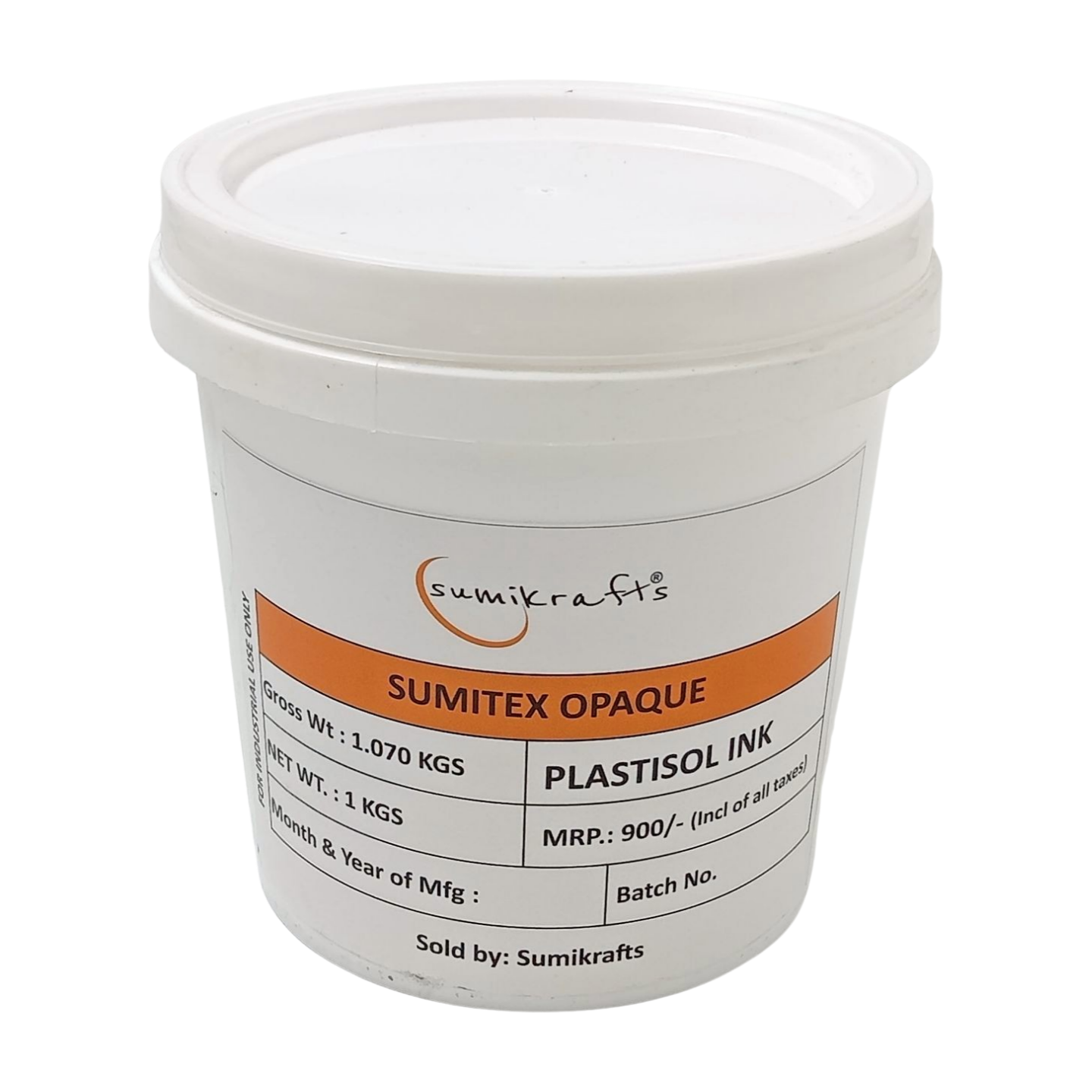

sumikrafts sumitex opaque white 1kg(1000gm) plastisol ink for screen printing on textile and apparel

Characteristics of Plastisol Ink:

Composition: Plastisol ink is made from PVC (polyvinyl chloride) particles suspended in a plasticizer. This gives it a thick, creamy consistency that is easy to work with in screen printing.

Opacity: It is highly opaque, making it excellent for printing on both light and dark fabrics. The colors are vibrant and solid.

Durability: Plastisol ink is known for its durability. Once cured, it forms a tough, flexible layer on the fabric that can withstand many washes without fading, cracking, or peeling.

Versatility: It can be used for a wide range of effects, from simple solid colors to more complex designs like high-density prints and 3D effects.

Curing: Plastisol ink requires heat to cure. Typically, it needs to be heated to around 320°F (160°C) to fully cure and adhere to the fabric. This is usually done using a conveyor dryer or a heat press.

Advantages of Plastisol Ink:

Ease of Use: It doesn’t dry out in the screen, making it easier to work with over longer periods compared to water-based inks.

Vibrant Colors: The opacity and consistency of plastisol ink allow for bright, bold prints that stand out.

Versatility: Suitable for a variety of fabrics and can be used to create a range of effects.

Durability: Produces prints that last a long time without significant wear.

Applications:

Plastisol ink is widely used in the apparel industry for:

T-shirts and other casual wear

Sports uniforms

Promotional items

Fashion prints

Its ease of use, durability, and vibrant color output make it a preferred choice for many screen printers, especially for larger production runs.